Announcement highlights the official launch of the company

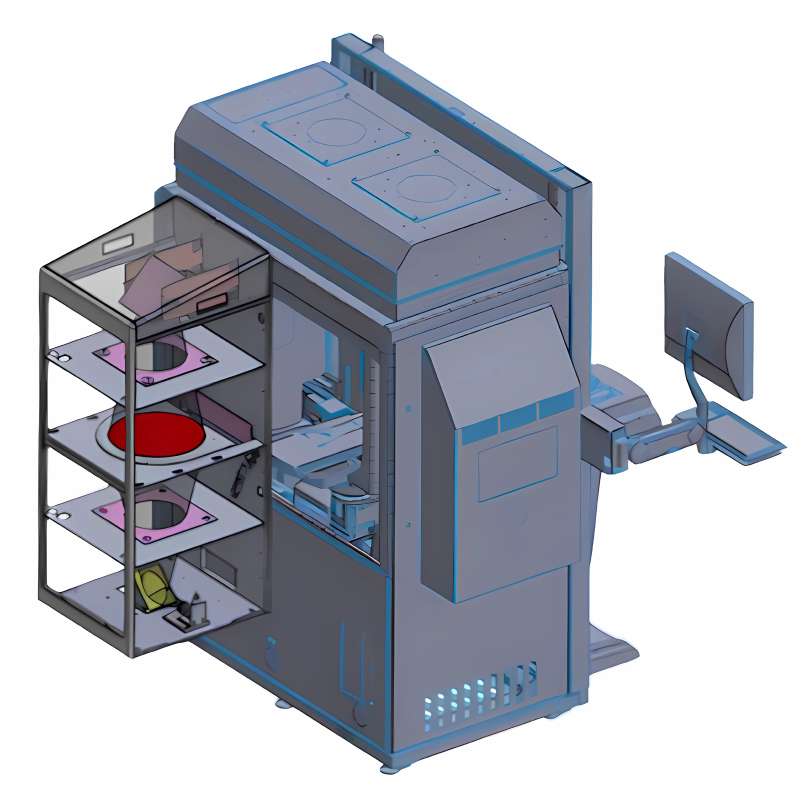

San Jose, Calif. (January 1, 2020) — Nano Span Technologies, LLC (Nano Span), a leading provider of production inspection and metrology equipment, today announced the commercial availability of the IRQuickScan (IRQS) product line. The IRQS product line offers both standalone and fully automated tools for through-substrate micro and macro inspection requirements of silicon, silicon carbide, gallium nitride, diamond, and glass substrates. According to Barton Katz, President and Chief Commercial Officer of Nano Span, “IRQS is a state-of-the art inspection and metrology tool that is revolutionary in the semiconductor equipment marketplace. It’s the first system to utilizes a proprietary infrared detection scheme to quickly characterize internal defects of various substrate types including silicon, silicon carbide, diamond, and glass as well as bonded substrates for voids, cracks, and delamination. It detects and locates defects and anomalies in X, Y, and Z dimensions down to below 1 micron in less than 5 seconds per substrate.”

Nano Span offers both macro and micro inspection and metrology products for wafer and applications in R&D and HVM environments. Sherlock, IRQS, and Clarity Pro encompass the core of the Nano Span product line for surface, sub-surface, and through substrate applications.

About Nano Span Technologies

Nano Span Technologies manufactures defect inspection and metrology equipment for customers involved in Silicon Wafer Characterization, Silicon Carbide (SiC) Ingot and Wafer Characterization, Bonded Wafer Characterization, Wafer Stress Characterization, and Glass Panel Inspection. Nano Span Technologies was founded by industry veterans and has been designing and manufacturing semiconductor manufacturing equipment since 2018.

More Information:

For more information on Nano Span Technologies and their full line of products, please visit www.nanospantechnologies.com or contact Nano Span Technologies directly at info@nanospantechnologies.com.